Automotive interiors play a crucial role in providing comfort, style, and a luxurious driving experience. The production of automotive interiors requires precision and attention to detail to achieve the desired quality and aesthetics. In recent years, CNC cutting machines have emerged as game-changers in the automotive industry, revolutionizing the manufacturing process of automotive interiors. In this blog, we will explore how CNC cutting machines are transforming the production of automotive interiors, enabling precise and complex cuts for upholstery, leather, and other materials, ultimately leading to enhanced quality and aesthetics.

Precision and Intricate Cuts:

CNC cutting machines offer unparalleled precision in cutting automotive interior components. Whether it's upholstery, leather, or other materials, these machines execute cuts with exceptional accuracy. The precise cutting capabilities ensure that every piece fits perfectly, resulting in a seamless and polished interior finish.

Complex Design Execution:

Automotive interiors often feature intricate designs, patterns, and detailing. CNC cutting machines excel in executing complex cuts, allowing manufacturers to bring intricate design elements to life. From intricate stitching patterns on seats to precise cutouts for buttons and controls, these machines enable the realization of sophisticated and visually appealing automotive interiors.

Consistency and Reproducibility:

Consistency is paramount in automotive manufacturing, and CNC cutting machines provide manufacturers with the ability to achieve consistent results. Once a design is programmed into the machine, it can be replicated accurately, ensuring uniformity across multiple production runs. This consistency contributes to maintaining the brand's image and delivering high-quality interiors to customers.

Enhanced Efficiency and Productivity:

CNC cutting machines streamline the production process of automotive interiors, leading to improved efficiency and productivity. These machines can execute complex cutting patterns quickly and accurately, reducing manual labor and minimizing the time required for production. The automation provided by CNC cutting machines allows manufacturers to meet production demands more efficiently, resulting in faster turnaround times.

Material Optimization and Waste Reduction:

Optimizing material usage and reducing waste are crucial aspects of sustainable manufacturing. CNC cutting machines contribute to these goals by minimizing material waste during the cutting process. The advanced software used in these machines enables efficient nesting of patterns, maximizing material utilization. This not only helps in cost savings but also aligns with sustainable practices in the automotive industry.

Enhanced Aesthetics and Luxury:

Automotive interiors are designed to provide a sense of luxury and elegance. CNC cutting machines play a significant role in enhancing the aesthetics of automotive interiors by ensuring precise cuts and seamless integration of various components. The precise execution of intricate designs and patterns adds a touch of sophistication and elevates the overall visual appeal of the interior space.

Customization and Personalization:

CNC cutting machines enable customization and personalization in automotive interiors, catering to individual customer preferences. From personalized embroidery on seats to unique design elements, these machines empower manufacturers to offer bespoke options, creating a more personalized and exclusive driving experience for customers.

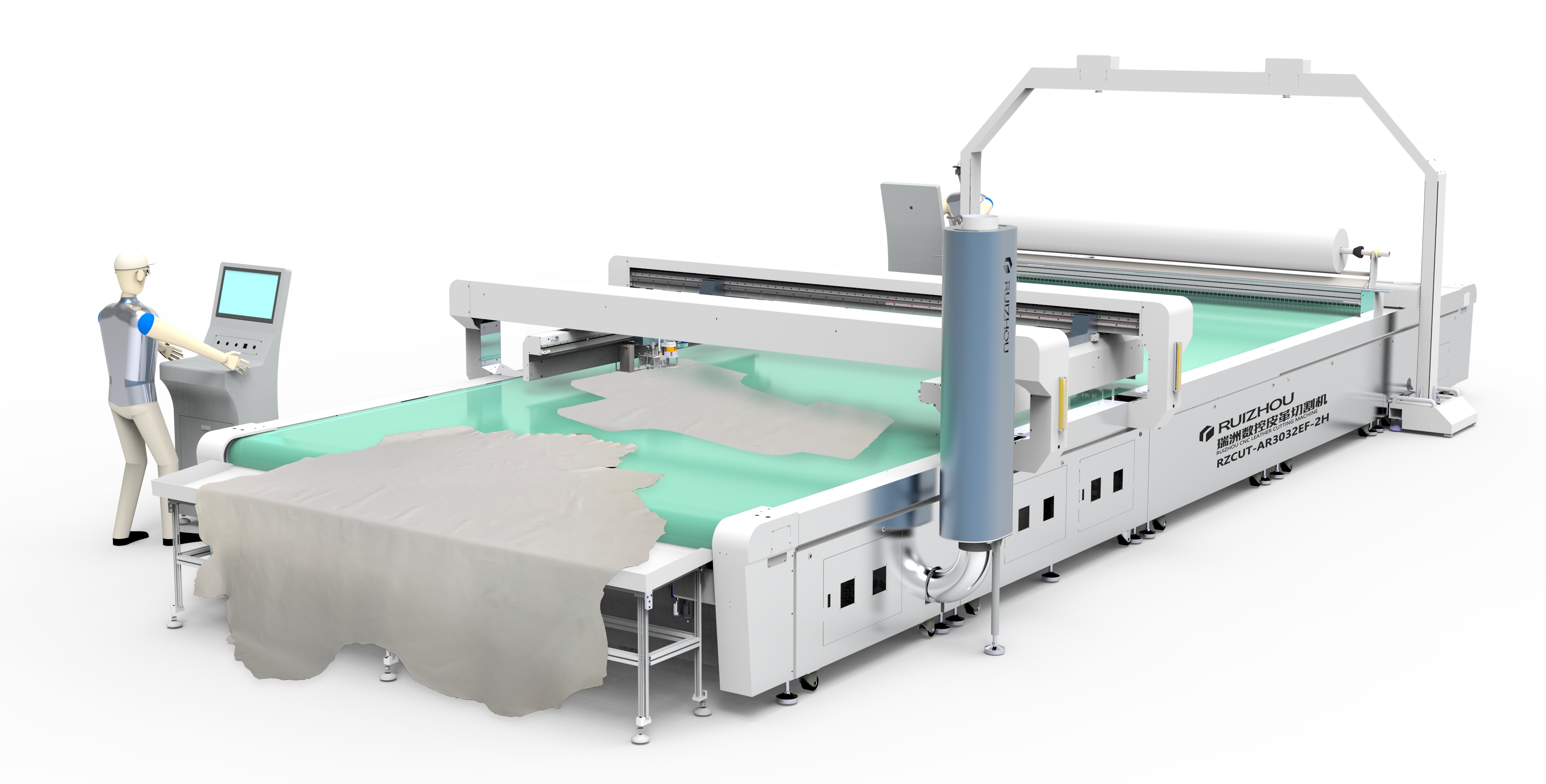

CNC cutting machines have revolutionized the production of automotive interiors, enabling precise and complex cuts for upholstery, leather, and other materials. By providing unmatched precision, efficiency, and the ability to execute intricate designs, these machines have transformed the automotive industry's approach to interior manufacturing. The integration of CNC cutting technology has enhanced the quality, aesthetics, and customization options available in automotive interiors, contributing to an elevated driving experience. As technology continues to advance, CNC cutting machines will continue to play a pivotal role in shaping the future of automotive interior production, enabling manufacturers to deliver interiors that are both visually stunning and of the highest quality.

Ruizhou has more than 28 Years dedicated to CNC Cutting Machine Manufacture. Our products have been well received by numerous enterprises and designing institutes from across the world. You are welcome to advise us your demands with specific descriptions, and a professional automotive interiors cutting solution will be offered accordingly.