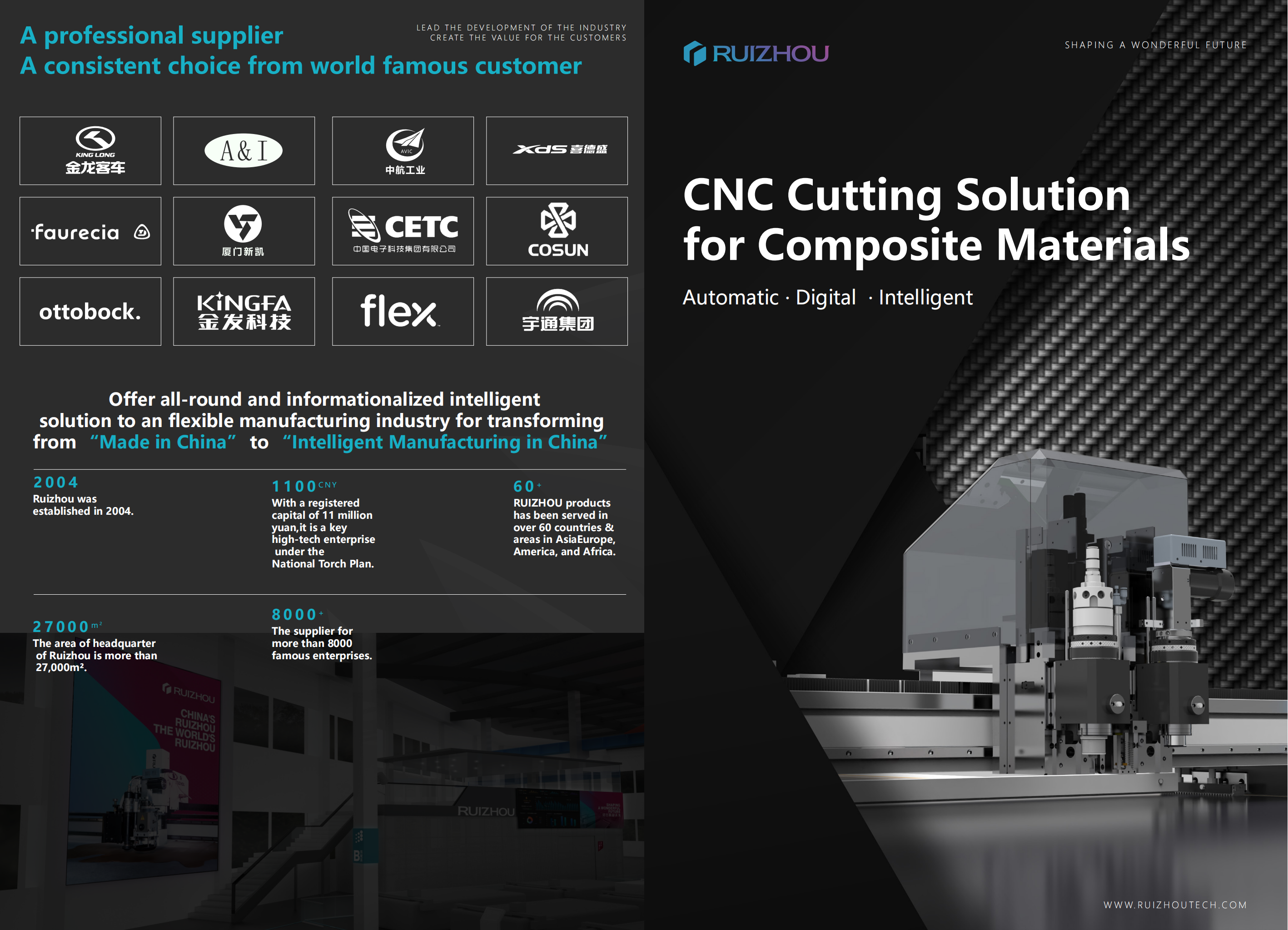

Ruizhou has more than 28 Years dedicated to CNC Cutting Machine Manufacture. Offer all-round and informationalized intelligent solution to an flexible manufacturing industry for transforming from "Made in China" to "Intelligent Manufacturing in China".

The aerospace industry demands the highest standards of precision, quality, and safety in the production of aircraft parts and components. With the rapid advancements in technology, CNC cutting machines have become indispensable tools in aerospace manufacturing. These machines play a critical role in shaping the industry by enabling precise cutting and machining processes. In this blog, we will explore the critical role of CNC cutting machines in the aerospace industry and how they contribute to the production of aircraft parts and components, where precision, quality, and safety are paramount.

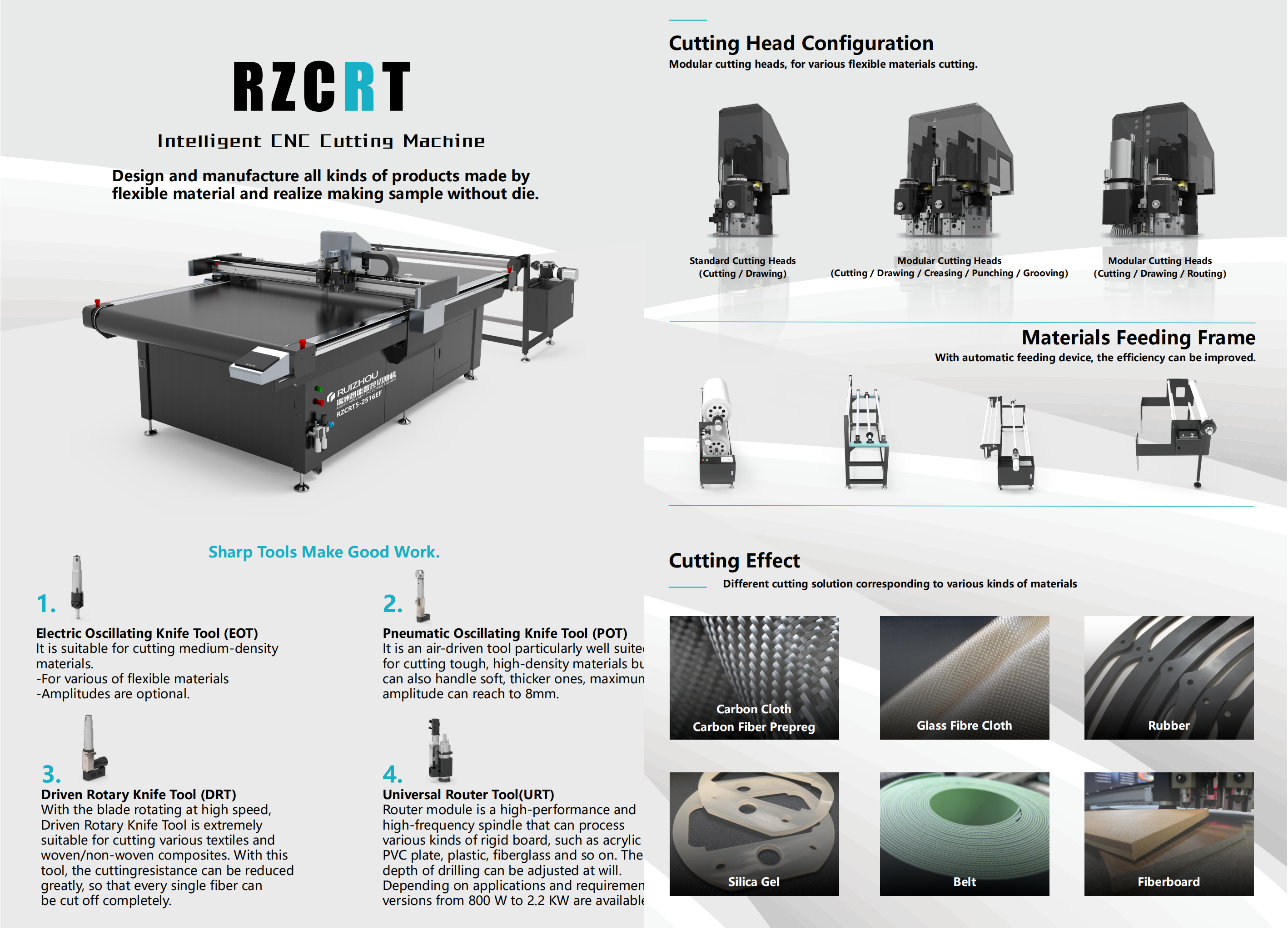

Precision Engineering: Precision is of utmost importance in aerospace manufacturing. CNC cutting machines offer exceptional precision in cutting and shaping aircraft parts and components. From intricate metal structures to composite materials, these machines execute cuts with unparalleled accuracy, ensuring that every component meets the exact specifications and tolerances required in the aerospace industry.

Complex Part Fabrication: Aerospace components often feature intricate designs and complex geometries. CNC cutting machines excel in fabricating these complex parts, enabling manufacturers to produce components that would be challenging or impossible to achieve using traditional manufacturing methods. These machines can execute intricate cuts, drilling, and milling processes with exceptional precision, ensuring the accurate reproduction of complex part geometries.

Material Versatility: The aerospace industry utilizes a wide range of materials, including metals, composites, and advanced alloys. CNC cutting machines are designed to handle these diverse materials, providing manufacturers with the flexibility to work with various materials as per the specific requirements of different aircraft components. This versatility contributes to the efficient production of high-quality aerospace parts.

Enhanced Efficiency and Productivity: CNC cutting machines streamline the manufacturing process in the aerospace industry, leading to improved efficiency and productivity. These machines can execute cutting, drilling, and machining processes in a highly automated and precise manner, reducing the reliance on manual labor and minimizing the chances of errors. The automation provided by CNC cutting machines enables manufacturers to meet production demands efficiently, resulting in increased productivity and reduced lead times.

Quality Assurance and Consistency: Maintaining the highest quality standards is crucial in aerospace manufacturing. CNC cutting machines offer consistency and repeatability, ensuring that every part produced adheres to the required specifications. Once a design is programmed into the machine, it can be replicated accurately, ensuring uniformity across multiple production runs. This consistency not only enhances quality but also contributes to maintaining safety standards in the aerospace industry.

Safety and Risk Mitigation: The aerospace industry prioritizes safety, and CNC cutting machines play a vital role in ensuring the integrity of aircraft components. These machines execute precise cuts and machining processes, minimizing the risks associated with human errors. The use of CNC cutting machines enhances safety by reducing the chances of defects, material inconsistencies, and other potential issues that may compromise the performance and safety of aircraft parts.

Advancements in Composite Manufacturing: Composite materials have gained significant prominence in aerospace manufacturing due to their high strength-to-weight ratio. CNC cutting machines have played a crucial role in advancing composite manufacturing processes. These machines enable precise shaping, drilling, and trimming of composite materials, facilitating the production of lightweight and high-strength components, such as aircraft wings and fuselages.

CNC cutting machines have revolutionized aerospace manufacturing by enabling precision, quality, and safety in the production of aircraft parts and components. Their ability to execute complex cuts, work with diverse materials, and provide consistent and repeatable results has made them indispensable tools in the aerospace industry. As technology continues to evolve, CNC cutting machines will continue to play a critical role in shaping the future of aerospace manufacturing, contributing to the production of aircraft parts that meet the highest standards of precision, quality, and safety.

RUIZHOU is a gold supplier in soft material cutting area around the word. Welcome to contact with our team, and a professional aerospace industry cutting solution will be offered accordingly.