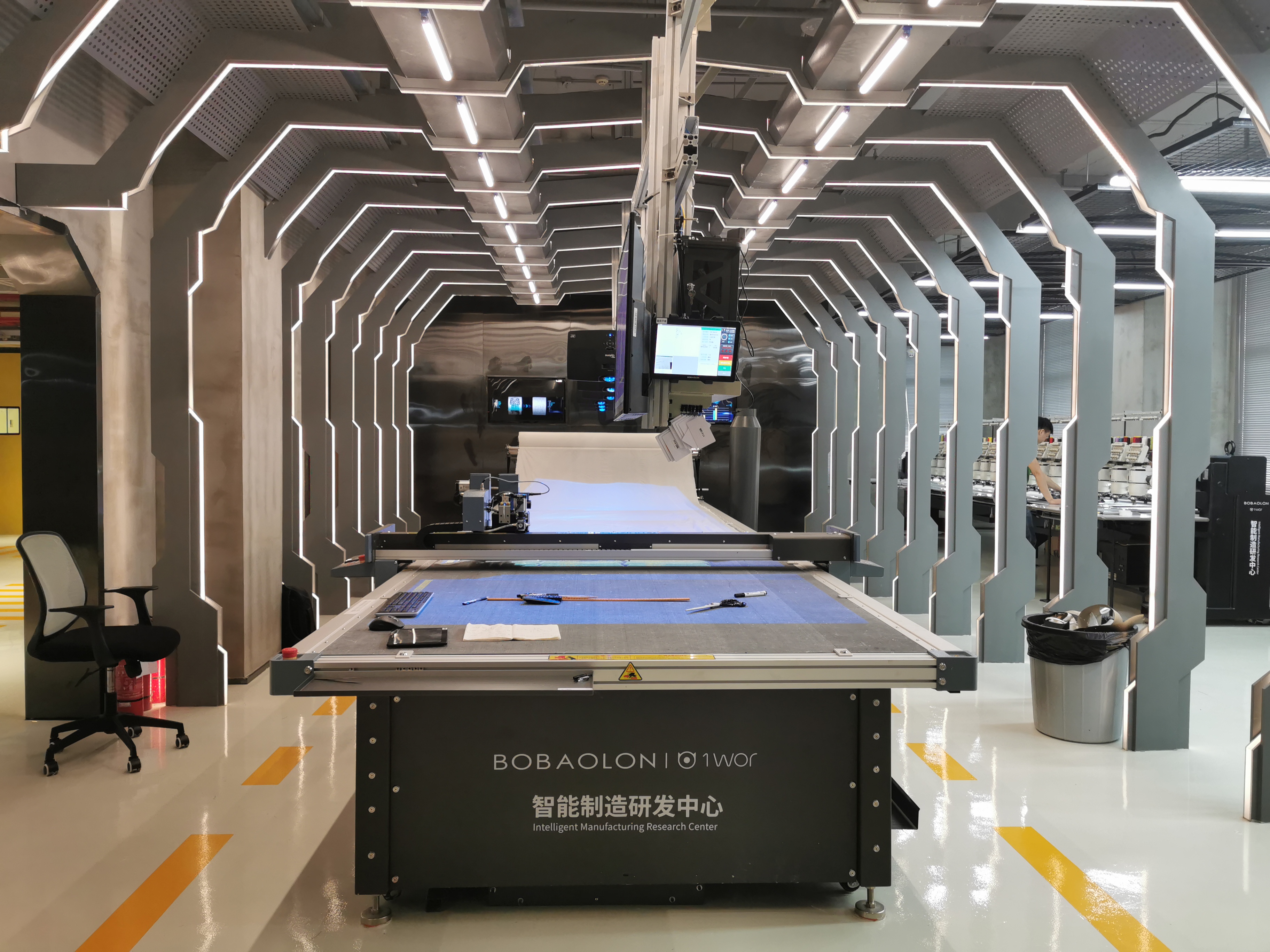

In the continuous development of manufacturing, maintaining accuracy is crucial, especially when using advanced tools such as knife cutting machines, CNC cutting machines, and digital cutting machines. Ensuring cutting accuracy not only improves product quality, but also optimizes efficiency, reduces waste and operating costs. So how to ensure the cutting accuracy of knife cutting machine? Here are some key strategies for achieving optimal cutting accuracy using these precision machines.

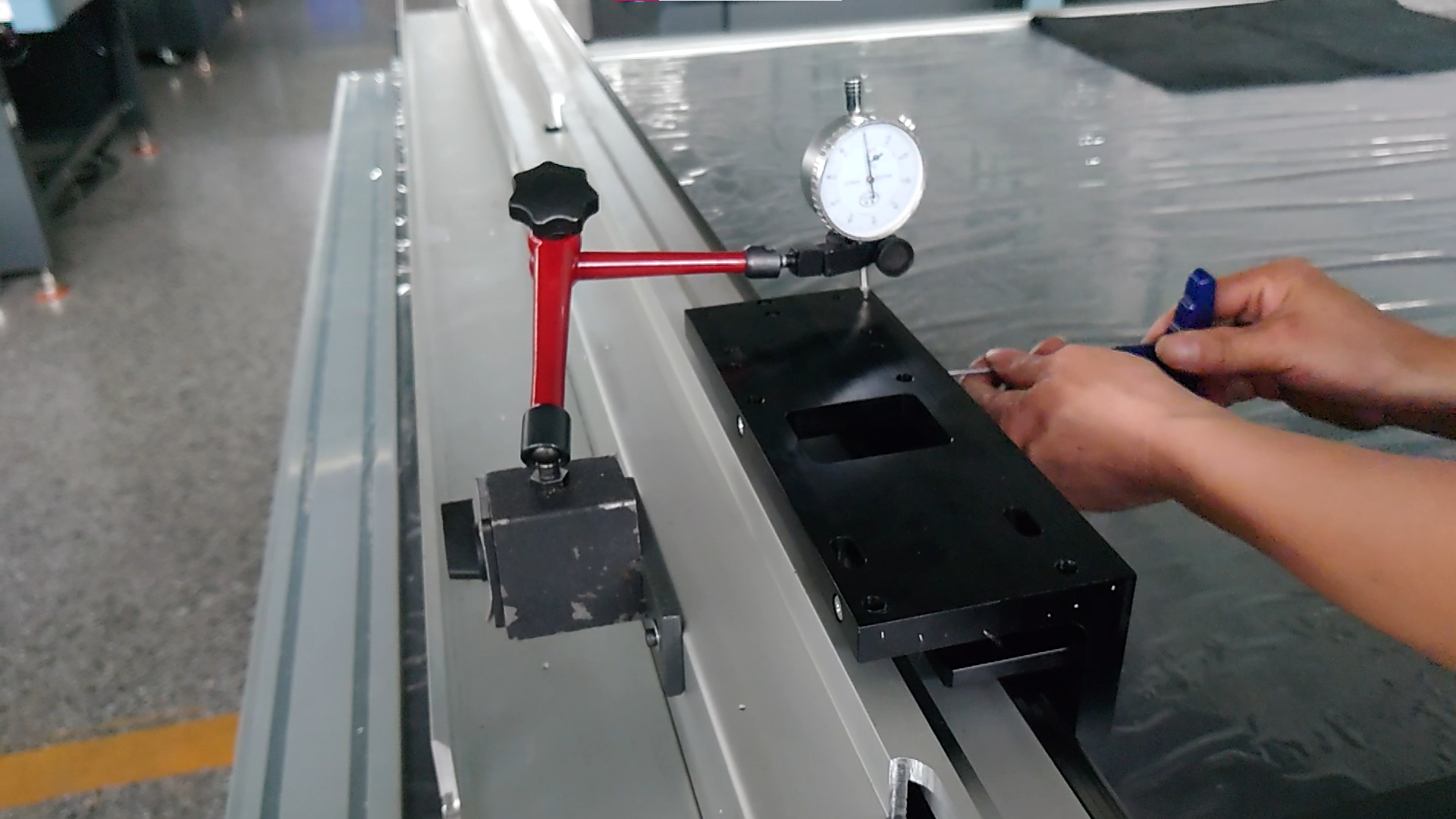

1. Regular Maintenance and Calibration

Consistent maintenance is crucial for the lifespan and accuracy of knife cutting machines. Regularly check the wear and tear of the machine,especially focusing on the cutting blades and the drive mechanisms. Regular calibration should be carried out to ensure that the machine settings comply with the manufacturer's specifications. This process helps to maintain precise cutting and avoid deviations.

2. High-Quality Blades and Tools

The quality of the cutting blades directly impacts the cutting accuracy. Investing in high-quality, durable blades is essential. For CNC and digital cutting machines, using the appropriate tools and accessories recommended by the manufacturer can make a significant difference. Regularly replacing worn-out blades is necessary to maintain sharpness and precision.

3. Proper Material Handling

The material being cut should be handled with care. Ensure that the material is flat and securely held in place to prevent any movement during the cutting process. Using vacuum tables or clamps can be effective in stabilizing the material, which is particularly important for digital cutting machines that operate at high speeds.

4. Accurate Software Settings

For CNC cutting machines, software settings play a crucial role in determining cutting accuracy. Ensure that the design documents are clean and error free. Properly configuring cutting parameters such as speed, pressure, and tool path can significantly improve accuracy. Regular software updates and training for operators can help fully utilize the potential of the machine.

5. Operator Expertise

A skilled operator can make a considerable difference in the cutting accuracy of these machines. Appropriate training and experience enable operators to promptly identify problems and troubleshoot them. Investing in continuous training programs for operators can better operate machines and improve overall performance.

6. Environmental Factors

Environmental conditions, such as temperature and humidity, can affect the performance of knife cutting machines. Ensure that the machine is operated in a controlled environment to minimize these impacts. Keeping the workspace clean and free from dust and debris also contributes to maintaining the accuracy of the cuts.

Conclusion, incorporating these strategies ensures that knife cutting machines, CNC cutting machines, and digital cutting machines operate at their highest accuracy levels. Regular maintenance, high-quality tools, proper material handling, accurate software settings, skilled operators, and a controlled environment are key factors in achieving precise and efficient cuts. By focusing on these areas, manufacturers can enhance product quality, reduce waste, and improve overall productivity.

Ruizhou is a leading provider of innovative solutions in the knife cnc cutting machine. RUIZHOU products have been widely applied in soft materials related areas, such as: footwear, garment, leather products, bags, cartons, lamps, composites, automotive interior, aircraft interiors, etc. .

For more information or to schedule a meeting with our team, please contact with us.